Layouts in Boxes

A Very Small Garden Railway!

This little Inglenook switching layout, the Down & Dirty RR, is contained in a window box, 29″x7″ (74×18 cm). Actually, the box was already being used by my wife to raise a few herbs — so I carefully laid in some temporary HOn30 trackage (9mm gauge), attached a power pack to the leads, and ran some antique AHM Minitrains. Everything worked just fine (although dirt balls and dropping leaves tended to be siginificant hazards).

This tiny mockup was made to explore an idea from Emrys Hopkins: to make a small-scale switching layout in a window box, where it could be out of doors but operated from inside simply by opening the window and attaching the power!

If I were making this railroad as a permanent micro layout, I would seat the track more firmly, provide for drainage, run the wiring through underground conduits, and plan the vegetation a little more carefully. But what a great way to have a garden railway in your vest pocket!

Anyone up for designing an On30 or Gn15 layout in the same space?

Layout in a Shoebox!

Carl’s Imports is an OO9 / HOn30 layout built in a shoebox. It’s completely self-contained — hook up a controller, and off you go!

Carl’s Imports is an OO9 / HOn30 layout built in a shoebox. It’s completely self-contained — hook up a controller, and off you go!

For the purposes of this design, we contacted our consultant, Bart Bakker in the Netherlands, about men’s shoebox sizes in Europe. Turns out they’re about the same as in the U.S. — varied! So we picked an average size that’s available nearly anywhere — 13″x7″x5″ (33x18x12 cm).

This layout is designed with the box on its side, so the real estate used for trackage measures 13″x5″, and the opening in front is 7″ tall.

It’s a waterfront scene, rimmed by multi-story buildings that reach to the top of the box. The layout itself is built on a slab of 2.5 cm (1″) foam, which can be cut away to form the quayside.

Purpose of the little layout is to haul goods to the Warehouse siding (front left), then bring carloads from the warehouse to the quayside for loading onto small cargo vessels. Secret heart of the layout is a sector plate hiding inside the warehouse, large enough to hold a small, four-wheel locomotive and a single car. There’s an additional source of surreptitious supply inside the building labelled “IMPORTS” (which is exactly what happens there).

Cars are easily added to the layout and removed via this convenient backdoor. Need to run around a car? Push it into the IMPORTS building, where an Invisible Hand removes it from the track, allows the locomotive to run through the building, then replaces the car — and voila! the loco has run around it! (This trickery makes it convenient to shunt the warehouse siding at the front left.)

All in all, this tiny diorama-like layout can provide an engrossing hour or two of operations — especially if the crane on the IMPORTS building is made into a working model! And when the operations are over, just unplug the controller, put it in your pocket, fix the shoebox lid in place, and head for home with your layout under your arm!

(Readers are cordially invited to design their own shoebox layouts and share them with the micro layout community through these web pages. Just e-mail me a sketch! If there’s enough interest, we’ll create a new section in the Gallery devoted to Shoebox Layouts!)

Dutch Layout in a Pencil Box

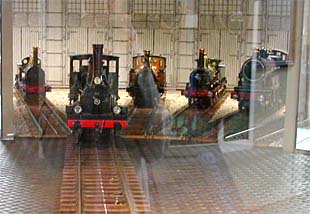

At the National Railway Museum in Utrecht, the Netherlands, there’s a turntable about two meters in diameter where visitors can select a priceless locomotive model (scale 1:10) they would like to see. The engine runs onto the turntable and makes a full turn, the public says “Ahhhhh,” and then the loco retreats happily to its track.

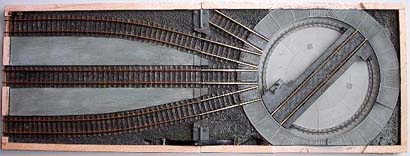

This scene inspired Bart Bakker to build Finnegan, an HO scale model of the museum installation, which he placed in a child’s pencil box that is slightly smaller than an A4 sheet of paper.

Named for a famous railroad poem (see story below), the layout went through a series of transformations as it grew in Bart’s imagination. At the beginning, it was designed to be a showplace for locomotives just as in the Museum. But with only 11 mm height inside the box, Bart could not find a way to motorize the turntable. So he considered dropping the project for lack of drama.

But then he realized there was room for three spurs leading off the turntable — just like an Inglenook switching layout. If the turntable could accommodate a very small shunting engine plus one car, he could use the layout as an Inglenook puzzle! So he searched, and found a Bavarian Glaskasten (“glass box”), a very short steamer.

That development led to still other changes — Bart added a short spur to hold the little switcher, and procured another, larger locomotive to act as a road engine. Now, with five cars to be spotted on the three tracks, and two locomotives — a local switcher and a road engine — he was equipped for not one but two switching games to play!

And so this little layout lived up to the punch line of the poem — “On again, off again, gone again — Finnegan.” So Bart named it — Finnegan!

At the National Railway Museum, Utrecht, the Netherlands

Bart Bakker’s HO model built in a child’s pencil box

Game 1 — A three-car train arrives and is shunted

Game 2 — Three cars are assembled behind the road engine

Here are the setups for two Inglenook style games that can be played on this tiny layout. The turntable holds the road engine or the yard engine plus one car. Each track can hold three cars. Dice are used to select cars to shunt and their positions.

In Game 1, the road engine arrives with three cars. Rolling the dice determines where the incoming cars are spotted. After this switching job, the two remaining cars are assembled into an outgoing train, behind the road engine, which has been turned on the turntable.

In Game 2, the road engine is placed at the upper right, and is being serviced. Five cars are already spotted around the sidings. Rolling the dice determines which three cars will form an outgoing train, and in what order. The puzzle is to make up the train and ready it for departure behind the road engine.

And of course, Bart can also use the layout as a showplace for his locomotive models. And in addition, it can be used at the end of the fiddle yard at home on his FREMO modules. All in all, this very small layout can provide hours of entertainment in a space the size of two A4 sheets of paper!

(left) The pencil box unopened. (right) An aerial view of the entire Finnegan layout

Here’s the story of the poem — often attributed to Liam O’Flaherty but actually by Strickland W. Gillilan — that sparked the name of this innovate little layout. The story is set in Ireland.

“On the Great Western Railway there was a Roadmaster named Mike Finnegan. As Roadmasters do, Mike would head out whenever there was a derailment, supervise the cleanup, and wire in a report to headquarters covering the details of the event and its resolution.

“After one particularly nasty accident, Mike laid out the entire situation in his lengthy report. Headquarters, unimpressed, wired back for Mike to keep to the essentials and forego the nuances.

“A few weeks later, the Great Western’s top manifest dropped a dozen cars on the ground, and Mike went out to investigate. All night long the light burned as Finnegan toiled over the derailment report to be wired. As the sun came up it read, ‘Off again, On again, Gone again — Finnegan.’ ”

The phrase became immortal!

HOn30 / O9 in a Shoebox

Len Kaplan took on the challenge of designing a shoebox layout, and came up with this tidy little HOn30 / O9 car and loco repair shop in the 13″x7″ (33×18 cm) space of a typical men’s shoebox. Operations can be simple but interesting. Len describes his design this way:

“These repair facilities are possibly more interesting as ‘modules’ for an extended layout than as standalone layouts. Add a shoebox-sized mine head and a processing facility/interchange of some kind and you’ve got an entire industry in less than 2 square feet!

“The yard was designed assuming short cars — around 8′ in length, similar to those sold by Nigel Lawton — and a short (under 15′) yard locomotive. A ‘captive’ locomotive would probably be reasonable for this sort of facility and would definitely make operations easier since there’s no room for a runaround.

“I’ve tried to leave room for storing an extra locomotive — either working or possibly a ‘hangar queen’ — and for some type of narrow yard building between the main track and the small traverser/transfer table area.

“Operation consists of bringing in a train of ‘damaged’ cars, pulling them one- by-one onto the large turntable, and then pushing them over to the transfer table from which they may be moved manually to the appropriate track. Shipping out repaired cars would work in the opposite manner.”

This little layout can be carried under your arm, unboxed and put to work … and then packed away again in its shoebox after the operating session! It’s a terrific showplace for your carefully modeled narrow-gauge stock and locos. It’s also one of the few layouts in this gallery that is intended to be viewed and operated from 360 degrees — all angles!

World’s First Flat Panel Micro Layout!

A variety of ideas from readers (see below) have combined to become Amalgamated Mine #258 — a shadow-box layout designed to be hung on the wall, operated, and viewed much like a flat-panel television!

The layout contained within the box is a three-level working mine display, just four inches deep in a 30 by 20 inch frame using HO or OO scale. The Mine could be built in larger or smaller scales, with the frame size adjusted accordingly. Either standard or narrow-gauge (or a combination) could be used — there are prototype examples of virtually any combination!

The bottom level is a cutaway view of operations deep within the ground. We can see the bottom of the railroad-car lift, where small mine cars descend to be filled and rise to the upper track to be hauled away. A smaller spoils lift, where unwanted debris and rock are hoisted to the surface, provides continuing loads for the top-level rail line to haul over to the the tailings dump.

The middle level is the railroad’s mining branch, where loaded cars are hauled away to the offstage tipple where the ore is sorted and loaded into full-sized railroad cars. The empty mine cars are then returned into the adit and lowered to the working mine below. The operating core of this layout are the two lifts, which will need to be engineered to operate automatically — a real modeling challenge!

The other “hidden secret” of operating Amalgamated #258 is the two wall-mounted fiddle tracks at the left. Ideally these would be removable, mounted only when the line is in operation. Another engineering challenge might be to concoct a chute system where the loaded cars on the upper track can be automatically dumped and their contents descend into the empty cars waiting on the lower track! In this case, though, manual operation is also a possibility.

The entire display can be viewed in operation on all three levels at once, and is both educational and a lot of fun for spectators! I’ve suggested a frame for the shadow box, to display the layout like a piece of fine art. This can be as elaborate or as simple as you wish, painted in the decorator color of your choice.

Idea Sources for This Layout

The design for Amalgamated #258 combines ideas from a variety of people. Genesis of my plan came from my Bilevel Shoebox Layout, found in “Shoebox Madness”. Then Jon Songøygard, from Norway, designed another straight line layout (inspired by the same source) and drew a delightful conceptual picture of it.

Jon wrote, “You can put this layout on the wall in your living room! Perfect for those of us with ‘no space’ for a layout.

“This is a mining layout scene, surrounded by tall mountain cliffs and majestic woods. Standard gauge trains arrive from out of the woods at right, while the narrow gauge enters dramatically via a tunnel opening some scale feet above. From there, the tippers are emptied via chutes down to the standard gauge cars. After that, both trains need new supplies of fuel (and water, if they are steam engines), before they depart the same way they arrived.”

Notice that Jon has built some operating interest into this simple “picture frame” layout. As he points out, “Notice that the two trains will have to cooperate while unloading/loading, as the chute takes only one tipper at a time, and both trains will have to move back and forth quite a bit to accomplish the transfer sequence.”

Another fertile idea came from Alan Jarvis, from England, who wrote: “I am building a full G-scale metre gauge mine on the shelf above my computer. One half is inside/underground with ‘peek-a-boo’ style viewing ports; the other half is in the open. [Alan, please send photos when you’re ready! -Carl]

“It struck me that one could build an extensive mine operation on multiple shelves/bookcase with a lift at one end for access to the other adits and the surface. On the surface, clever use of a fishtank would give the effect of a slice through the ground.”

And finally, Carl Mosness, from the U.S., wins the honors for “Farthest Out Idea” with the following:

“I see three levels.

“The bottom level would be the inside of a mine. It would be the bottom of the elevator shaft. I was thinking of an enclosed auger — the mine cars could dump there and the ore would be lifted to the top level by the auger.

“The top level would be the top of the mine with some kind of dumping to the middle level (standard guage). Maybe a loop of narrow guage that would dump to the middle level.

“The middle level would be standard guage or narrow that would take the ore to a dock that has a barge tied to it. The ore would get dumped into the barge which has a tube that takes the ore to the bottom level to be loaded in the mine cars out of sight.

“If the auger worked I was thinking of calling it the Archimedes Mine.” [Gives a whole new meaning to the phrase, “We really screwed up that one!” -Ed.]

There you have it. A bunch of excellent ideas — Amalgamated Mine #258 is just one of the many possible designs suggested by this international trio of creative thinkers. Perhaps they’ll spark some creative thinking in you — if so, send us your ideas, you never know what they’ll lead to. All contributions are acknowledged and welcome here!